VEKAPLAN KD/ Wood COOLSKIN™

Properties

Increased impact resistance

Extremely good thermoformability and thermoformability

UV and weather resistant

Moisture resistant

Swelling resistant

Good chemical resistance

Good mechanical properties

Recyclable

Surface finishing

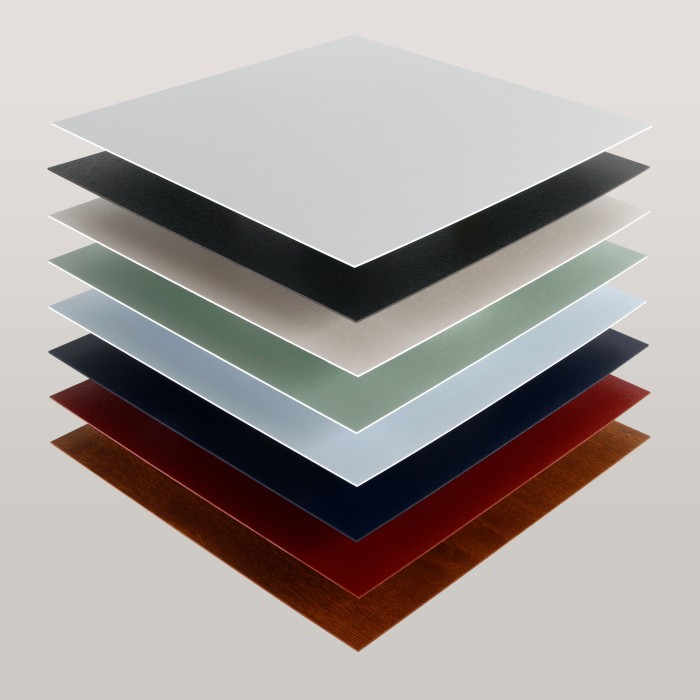

VEKAPLAN KD/Wood COOLSKIN™ is available in different versions.

For foils with woodgrain embossing, we enable further surface refinement through additional embossing.

Click on an info point on the image to get further information.

Decor examples

In the color selection you will find a wide variety of colors and finishes in the range for door panels. From exciting, vibrant colors to the latest wood designs, it's a product range that we and our customers are really proud of.

Areas of application

Impressions

Technical properties

Product features | Standard | Value |

|---|---|---|

Thickness [mm] | - | 1,4/1,5/2/3 |

Density [g/cm3] | DIN EN ISO 1183 | 1,38-1,43 |

Tensile modulus of elasticity [MPa] | ISO 527 (50 mm/min) | 2900/2700* |

Impact strength (Charpy) [kJ/m2] | ISO 179/1eU | without breakage |

Notched impact strength (Charpy) [kJ/m2] | ISO 179/1eA | 7,3/8,0* |

Tensile strength [MPa] | ISO 527 (50 mm/min) | 46 |

Flexural strength [MPa] | ISO 178 (2 mm/min) | 80 |

Shore hardness D | ISO 868 | 77/82* |

Coefficient of expansion [mm/mK] | DIN 53752 | 0,08 |

Vicat softening point [°C] | ISO 306 (B50) | 70/78* |

Heat deflection temperature [°C] | ISO 75-2 (1.8 MPa) | 60/70* |

Water absorption [%] | ISO 62 (after 216 h) | 0,09 |

*Values for VEKAPLAN Wood based on the standard |